Save Weight Space Application Time Material Cost

Conventional Polyimide Tapes

RockeTape™

- Weight and Thickness (20 Layers of 1 mil Conentional Polyimide Tape has 2x the thickness of 1 layer of RockeTape™ Polyimide)

- Application Time (Achieve the same temperature resistance with only 1 layer of RT-PI versus 20 layers of Conventional PI tapes)

- Material Cost (Avoid having to buy multiple rolls of Conventional PI tape)

RockeTape™ vs Traditional PI Tapes

layers of polyimide film provide the same thermal resistance of 1 layer of RT

1

+

The only material that combines low thickness, low thermal conductivity, & high temp resistance

1

mil

Lower thermal conductivity than standard high temperature tapes on the market

1

X

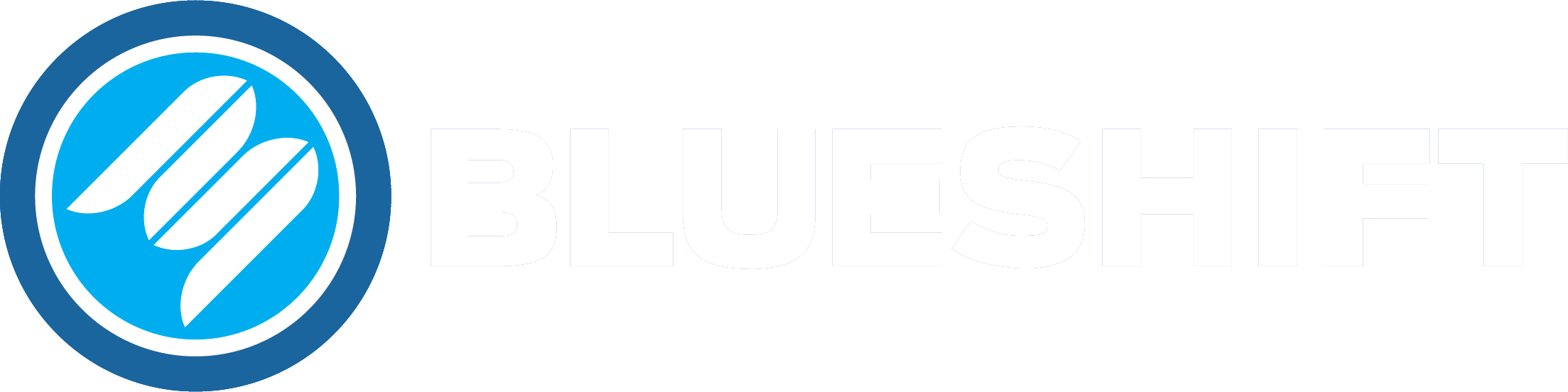

Case Study

The highest performing polyimide film tape alternative.

Check out this case study to see why RockeTape™ is changing industry standards.

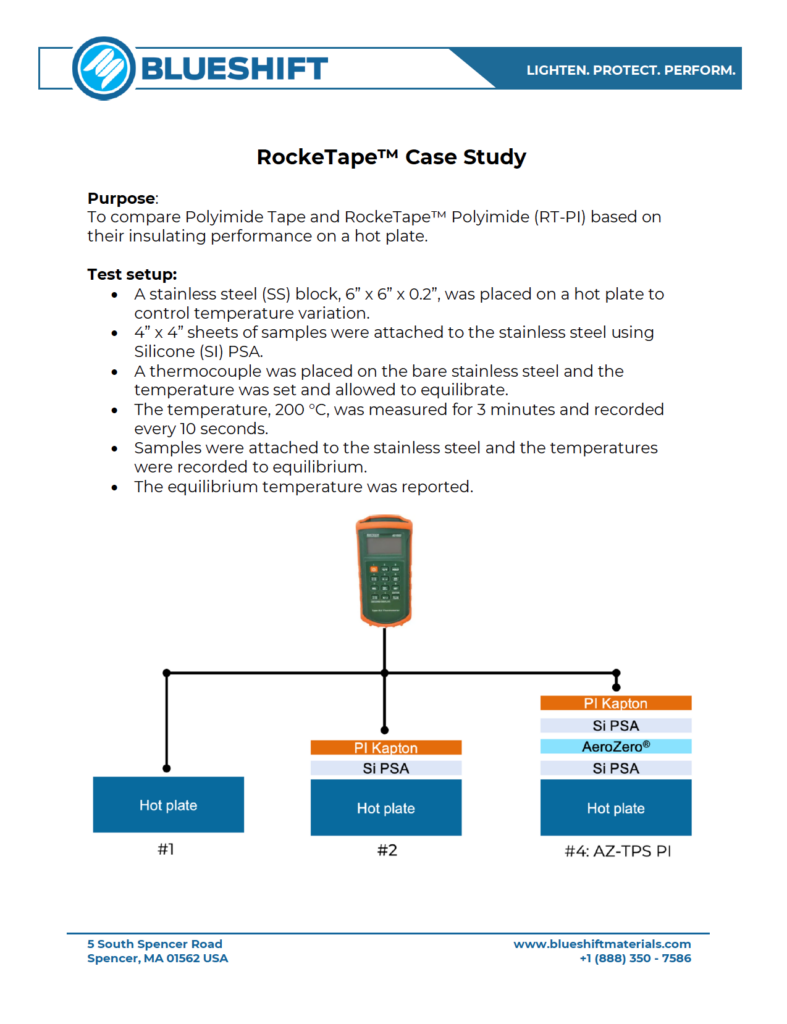

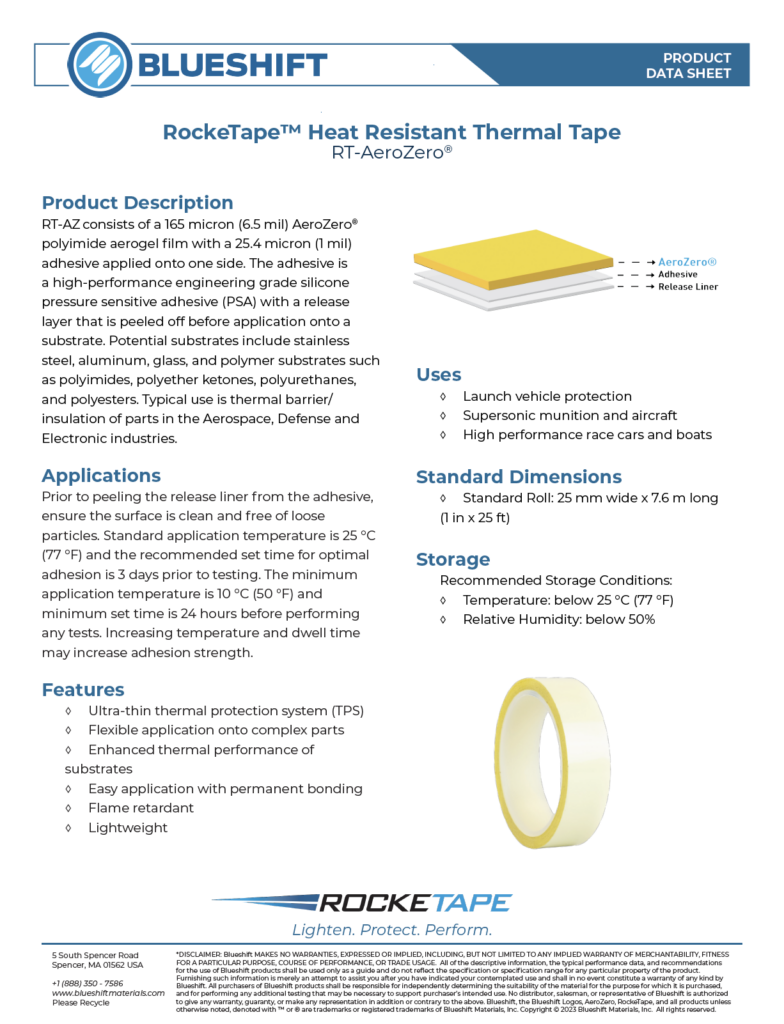

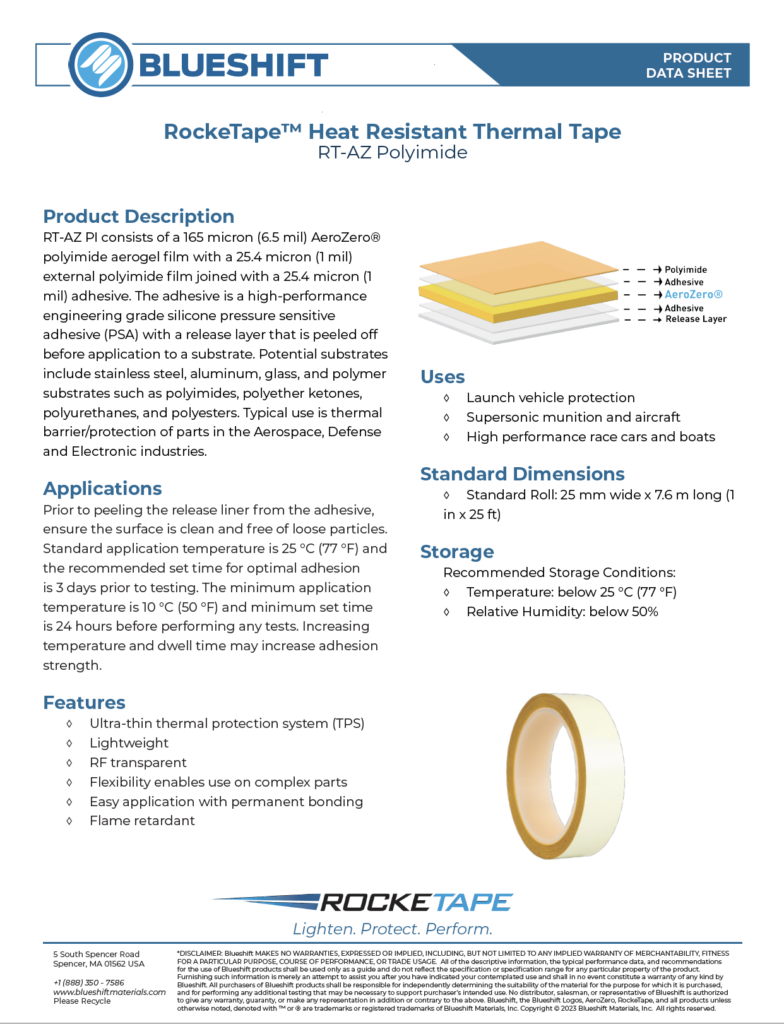

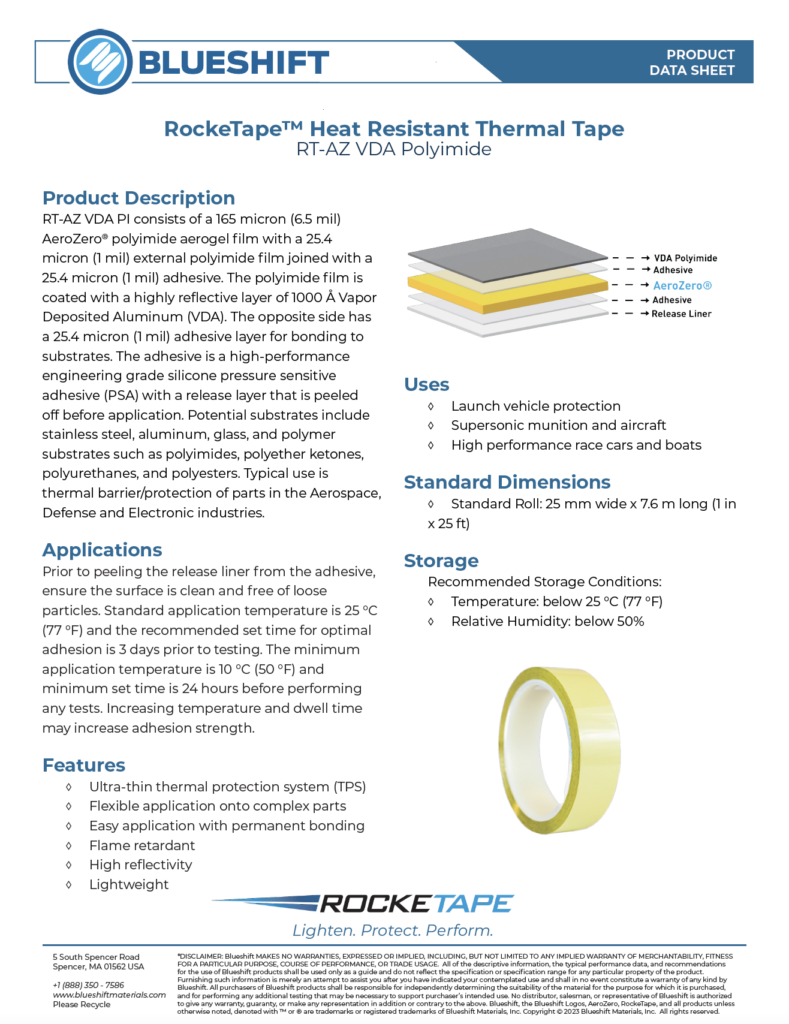

Downloadable Technical Data Sheets

These Blueshift product data sheets present specific installation & performance parameters for the RockeTape™ product range. Variations within the range employ different layers to product distinct performance profiles.