Frequently Asked Questions

We offer sample sheets of 8.5 x 11” for purchase and can have those mailed to you within 48 hours.

1. Our larger roll products can be purchased by reaching out to a salesperson through our contact form. We are happy to assist you in refining which product may suit your need best.

2. RockeTape™ can be easily purchased “off the shelf” on both DigiKey.com or Zoro.com.

Increasing the number of layers of AeroZero in a design provides minimal increase in thickness and weight, but results in a greater reduction in temperature through its interface.

- Graphite:

- Interior/exterior use

- XY heat spreading can help prevent overheating from a hot spots

- High temperature protection (has been successfully integrated into designs that see 2,000 ºC for 1-2 mins)

- Aeroheating/contact heating

- Current uses: Rockets, Launch Vehicles, EVTOLs

- Polyimide:

- RF Transparent

- PTFE Alternative

- Ultra Low Dk/Df

- Current Uses: Antennas, Missiles, Cables

- Vapor Deposited Aluminum Polyimide:

- Interior/exterior use

- Low emissivity

- High reflectivity

- Current Uses: Satellites

We have a product development process. New products can be simple, incremental changes or wholesale material science development. Our process can take anywhere from a few weeks to over a year depending on the nature of the development you are looking for. Please see our resource request form. After filling it out, we can let you know whether the specified project is something we can assist you with and the expected timing, or whether it is something we do not have the ability to complete.

We currently offer two adhesive choices for our thermal protection systems:

- Silicone Aerospace Adhesive: A silicone adhesive known for its high temperature performance and excellent fire retardancy.

- Low Outgassing Adhesive: An acrylic adhesive that is used in demanding space & medical applications where low off-gassing is required. This acrylic adhesive should be used in applications where high temperatures and flame-resistant performance are not required.

- Medical Grade Adhesive: A silicone adhesive that, when introduced to body fluids, prevents toxins from leaching into the body.

- Inquire about other adhesive options.

We currently have two product lines that employ our polyimide aerogel technology:

- AeroZero: Our trademark polyimide aerogel product line. AeroZero is utilized in our thermal protection systems, our fire and thermal barriers, and RockeTape™.

- EDS: A version of our polyimide aerogel technology that is perfect for antenna applications. This material is known for its consistent structure, it’s speed, low Dk, and the absence of a phase change (in comparison with other materials like PTFE).

Many companies produce silica aerogels, but only a few produce polyimide aerogels. Of those that do produce polyimide aerogels, we stand alone in our ability to produce it in a thin-roll format that allows it to be easily bonded to other substrates such as graphite.

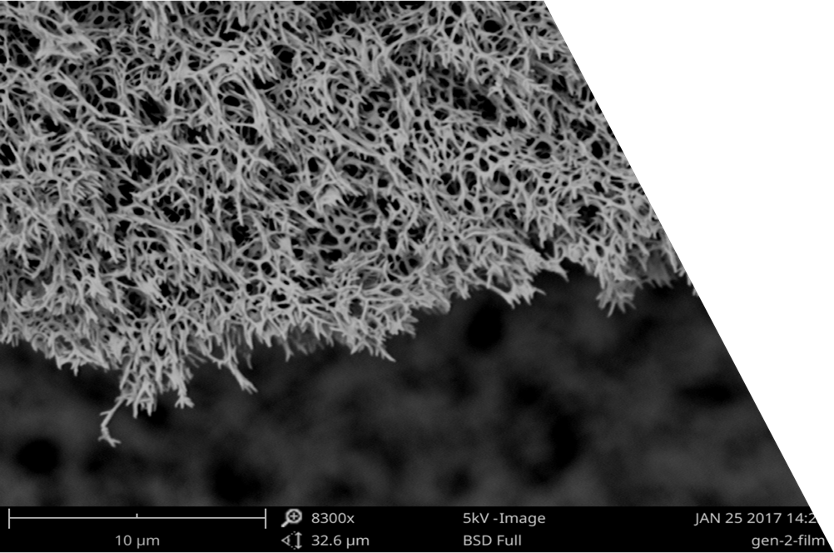

AeroZero is a thin, polyimide aerogel film that is flexible and durable. The film is 85% porous and produced at 165 microns (6.5 mil) thickness. AeroZero provides the thermal insulation, RF transparency, dielectric properties, and lightweight benefits of an aerogel with the ease of use and mechanical strength of a plastic film.

Polyimide aerogels are a 2-in-1 material technology. The clear advantage of using this material arises from its 85% air content that exists due to the material’s nano-porous structure. The high air content means that all of the properties that are inherent to air are also inherent in our material. Polyimide aerogels combine thermal conductivity and diffusivity, high heat tolerance, ultra-low dielectric properties, and a high strength-to-density ratio. The “Structured Air” of the material results in its low thermal conductivity, low dielectric constant, and lightweight nature. When combined with a robust polyimide shell, polyimide aerogels are able to have a high-temperature range, high flame/chemical resistance, and great mechanical strength. Our ability to produce polyimide aerogels in such a thin-roll format allows it to be combined with other substrates for enhanced thermal and RF performance (e.g., graphite, polyimide, VDA polyimide, etc…).

While traditional silica aerogels are flaky, dangerous to manufacture, and cumbersome to use, polyimide aerogels are safe from their inception to their end use. The material properties of the advanced material make it the perfect choice for transient or cyclical thermal events. Plus, due to our uniquely developed manufacturing ability, our polyimide aerogel can be produced in a thin roll-to-roll format that is easy to apply and conform to your design needs.

Have more questions?

Ask us your biggest thermal question