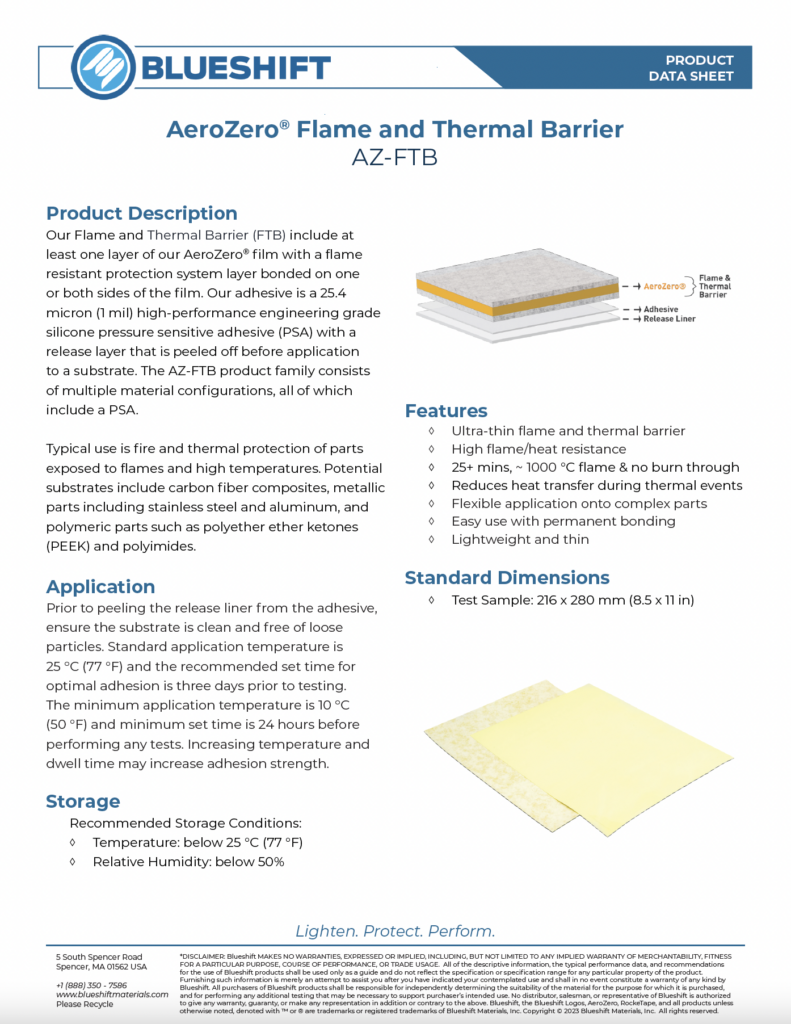

AeroZero®

Flame & Thermal Barrier

Our flagship flame and thermal barrier offers an unprecedented weight to performance ratio.

Watch it at Work

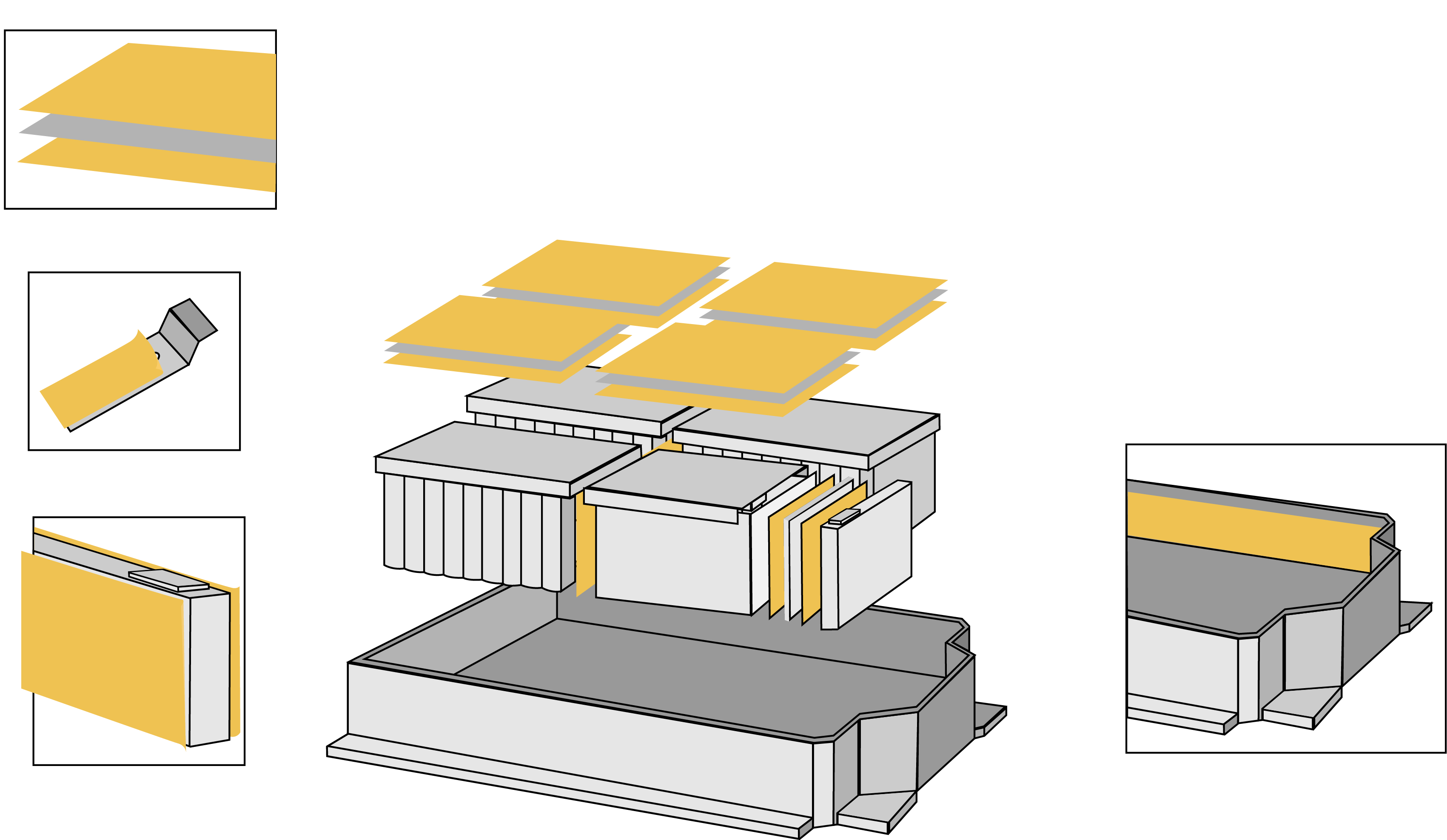

Use Cases

Prevents fire penetration

During thermal events

Provides Battery

Thermal Runaway Protection

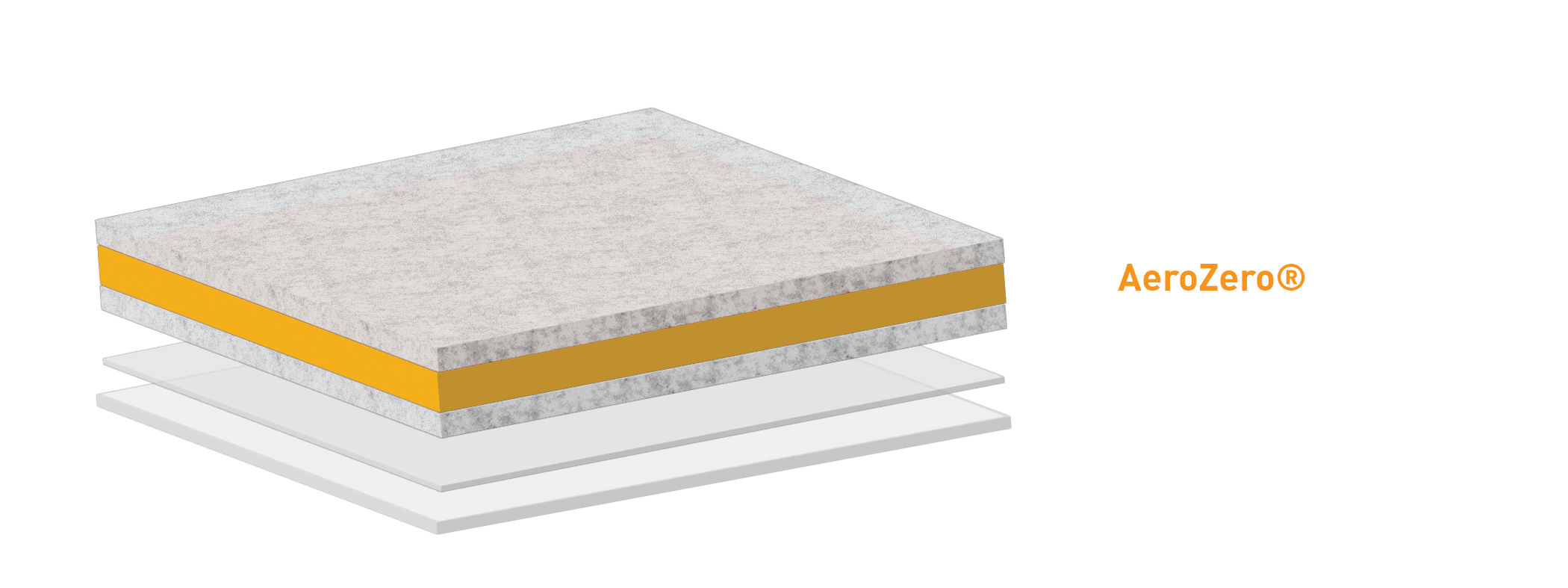

Intumescent coating, cork, & mica replacement

On lightweight structures

*One example of FTB configuration

Thin profile & Lightweight

46 mil

High Temp Protection

25+ mins, ~ 1,000 °C flame & no burn through

Flame Retardant

UL94-VTM0 certified