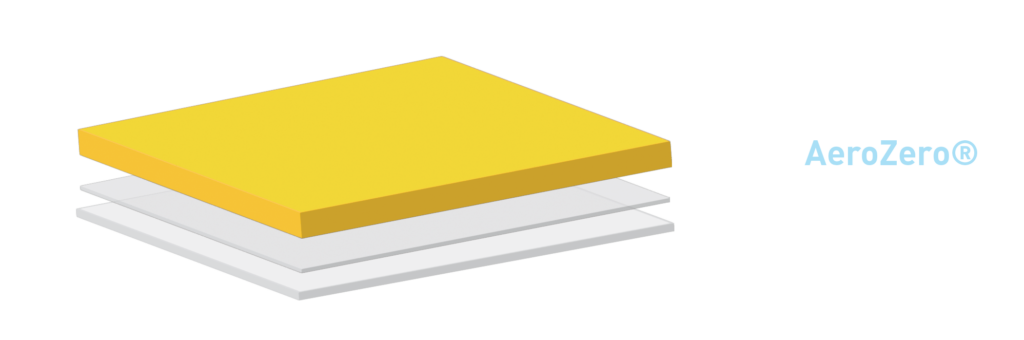

AeroZero®

Thermal Protection Systems

All thermal protection system start with AeroZero

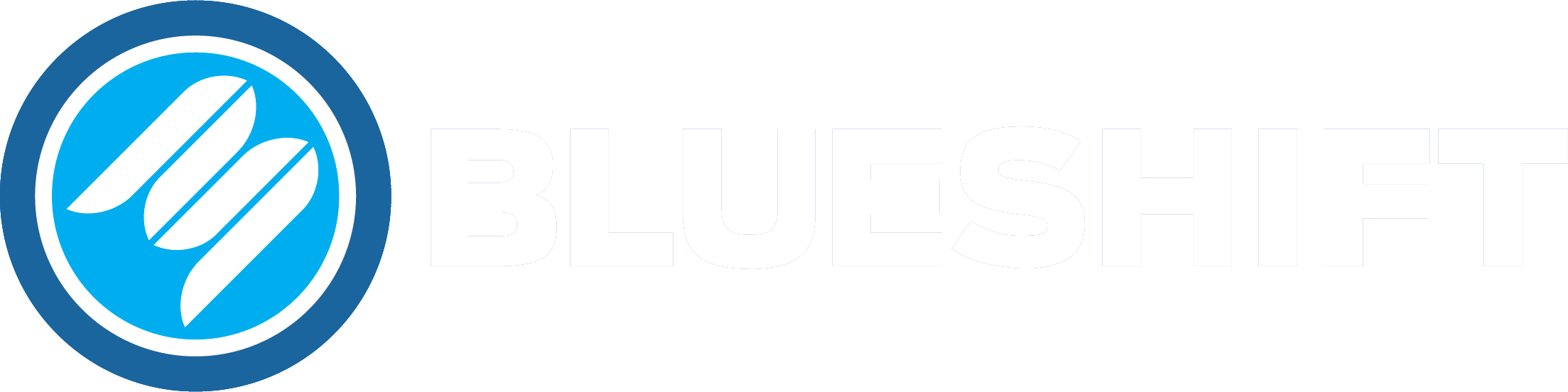

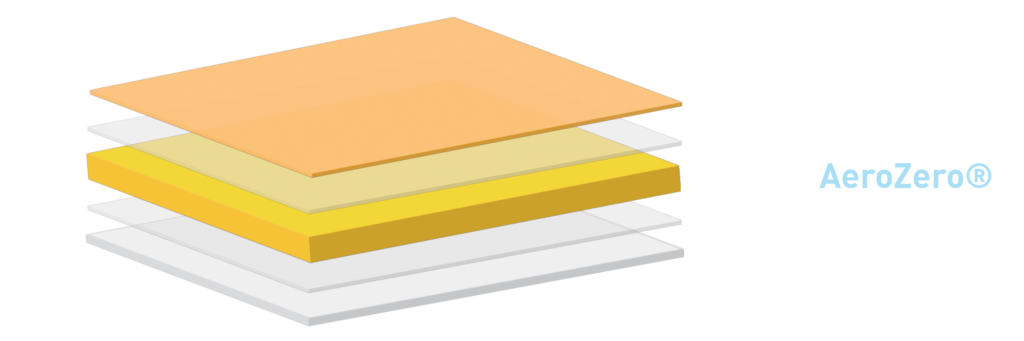

Thin profile & Flexible

7.5 mil

Flame Retardant

UL94-VTM0 certified

Lightweight and Flexible

85% air

Base AeroZero TPS

Areas of Success

Medical & electronic devices

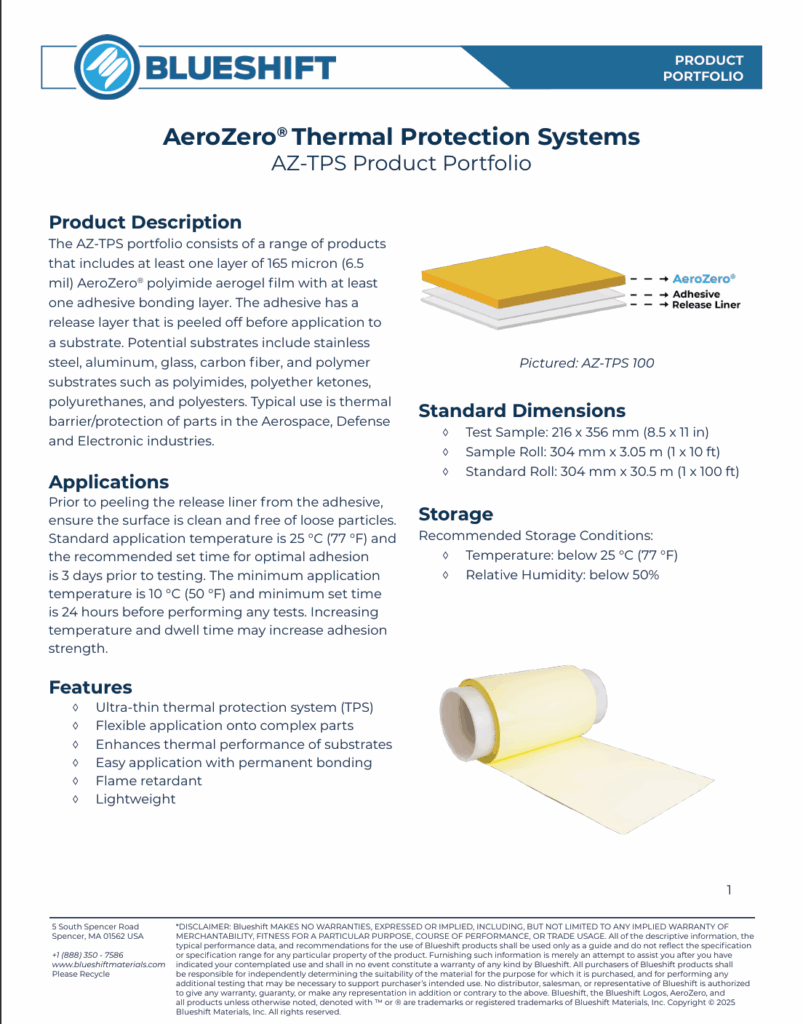

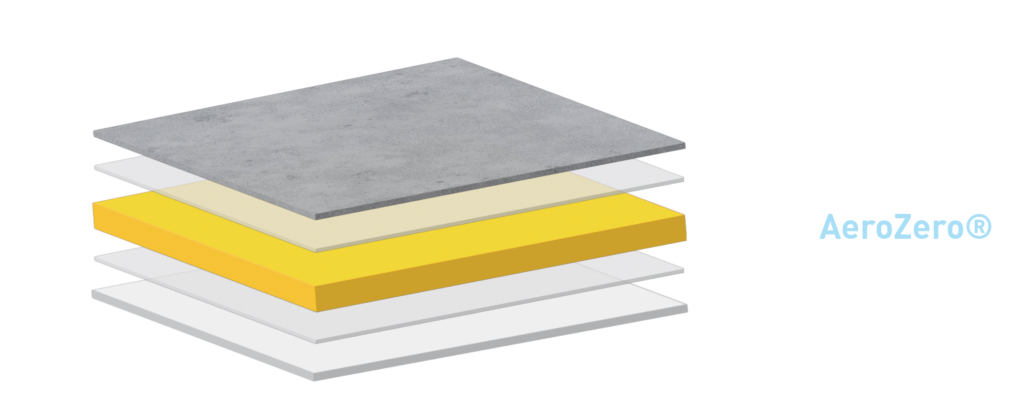

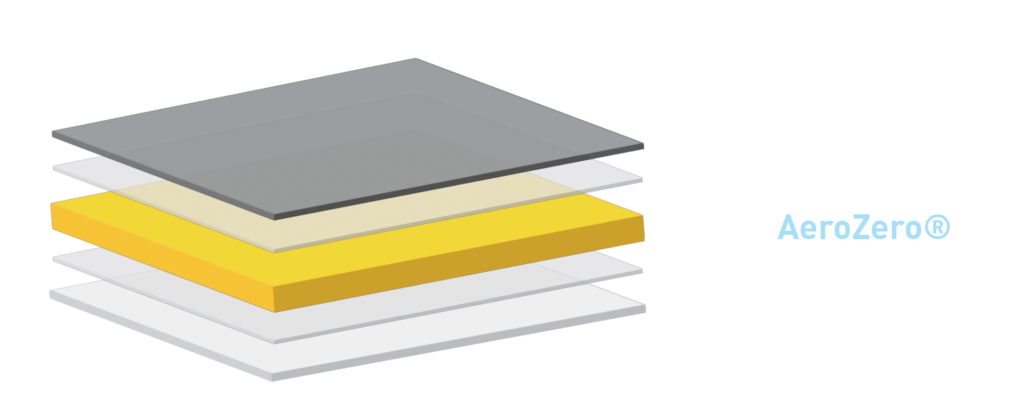

AeroZero TPS Graphite

Areas of Success

Rockets, Launch Vehicles, eVTOLs

Thin profile & Flexible

10.5 mil

Easy Application & Permanent Bonding

High Temp Protection

Successful use in designs that see 2,400 ºC+ for 1-2 mins

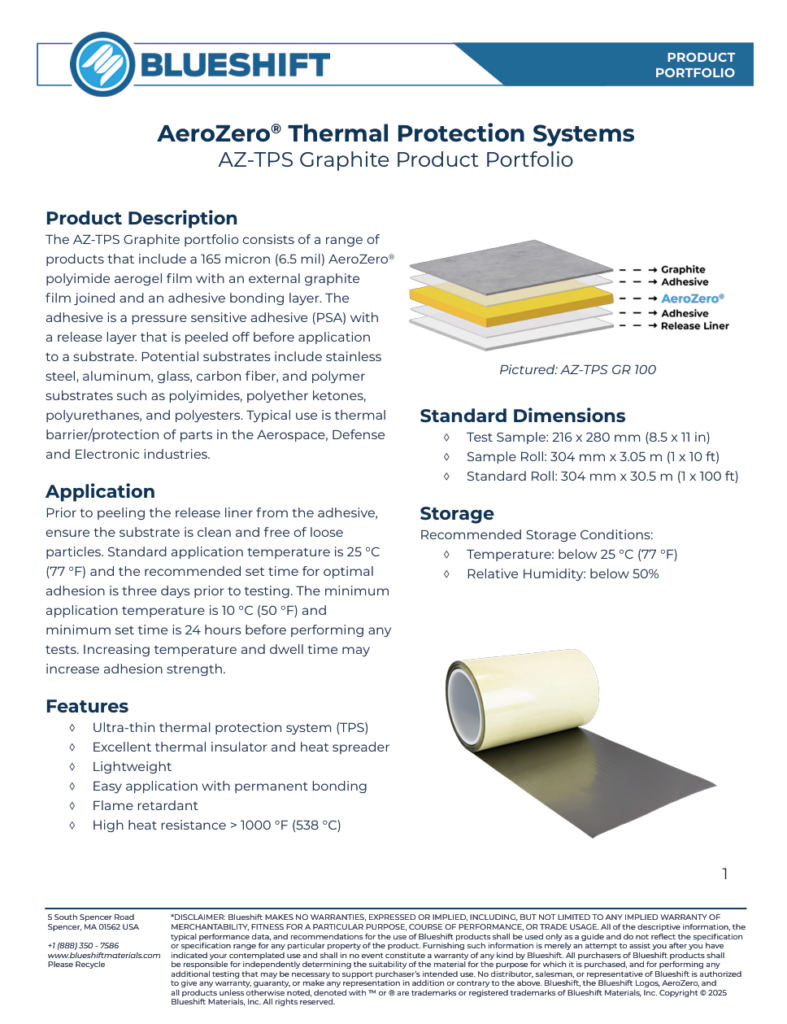

Thin profile & Flexible

9.5 mil

Easy Application & Permanent Bonding

RF Transparent

High Reflectivity

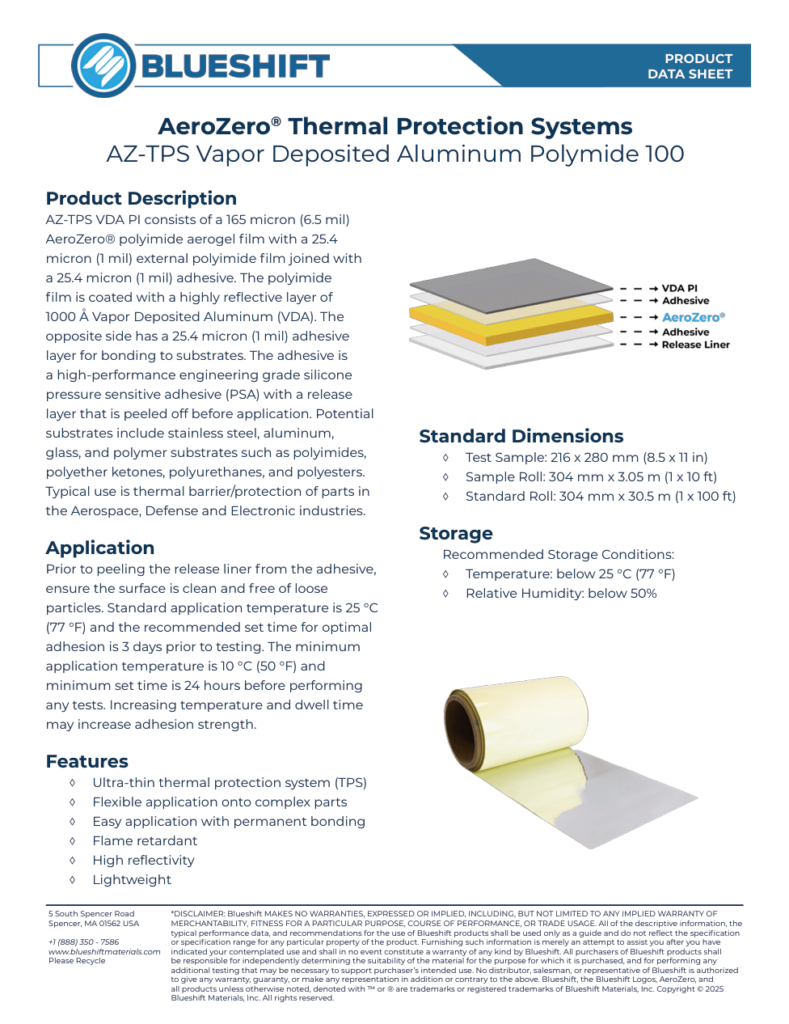

AeroZero TPS Polyimide

Areas of Success

Medical Devices, Electronic Devices

Thin profile & Flexible

9.5 mil

low Emissivity

AeroZero TPS VDA Polyimide

Areas of success

Satellites

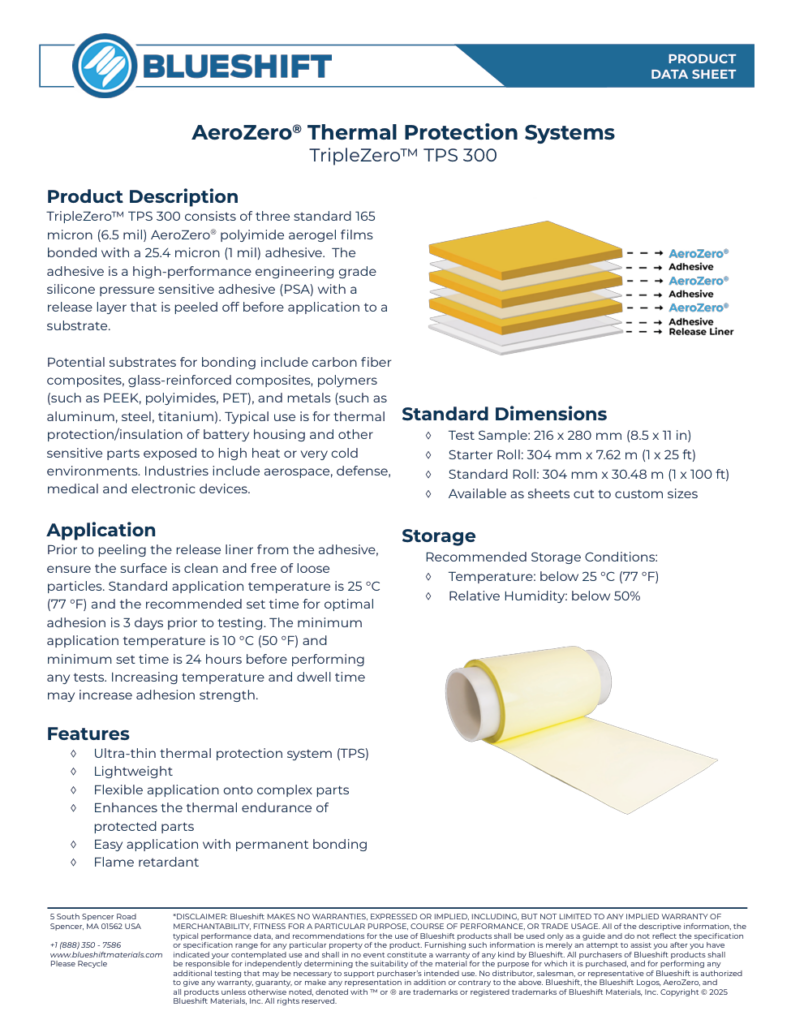

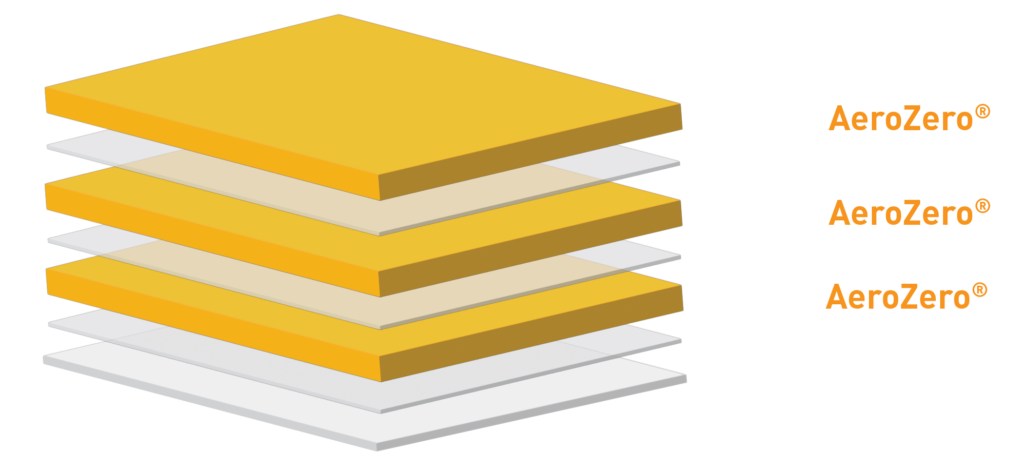

TripleZero™

Areas of success

eVTOLs, Launch Vehicles

Thin profile & Flexible

22.5 mil

RF Transparent

Easy Application & Permanent Bonding

Or Explore other customization options:

Substrate Type

Graphite

VDA Polyimide

Polyimide

Add more AeroZero® Layers

DualZero

TripleZero

QuadZero

Type of Adhesive

Aerospace Silicone

Low Outgassing

Medical Grade

Inquire For Others

Contact Us

Reach out to see what solution fits your design best.