Thermal Protection Systems

We are thermal material experts.

We believe in a world where design issues don’t hold you back, but propel you forward. We are a team of thermal material experts, scientists, and gifted engineers committed to developing and sharing our advanced material solutions. Our team’s passion is strengthened with every new issue we discover and every new idea we hear. We are Blueshift.

Brands We Partner With

Customer Testimonial

“Blueshift’s thermal protection system is light, thin and easy to incorporate into our strict design requirements, while producing exceptional thermal results.”

– Martin Schuebel, Lilium’s Senior Vice President Procurement

Our Products

All products integrate our core polyimide aerogel technology: AeroZero

Flame Barriers

For protection from direct flames. Our barriers are successful in protecting carbon-fiber composites when exposed to 1,000 ºC flame for 25 minutes.

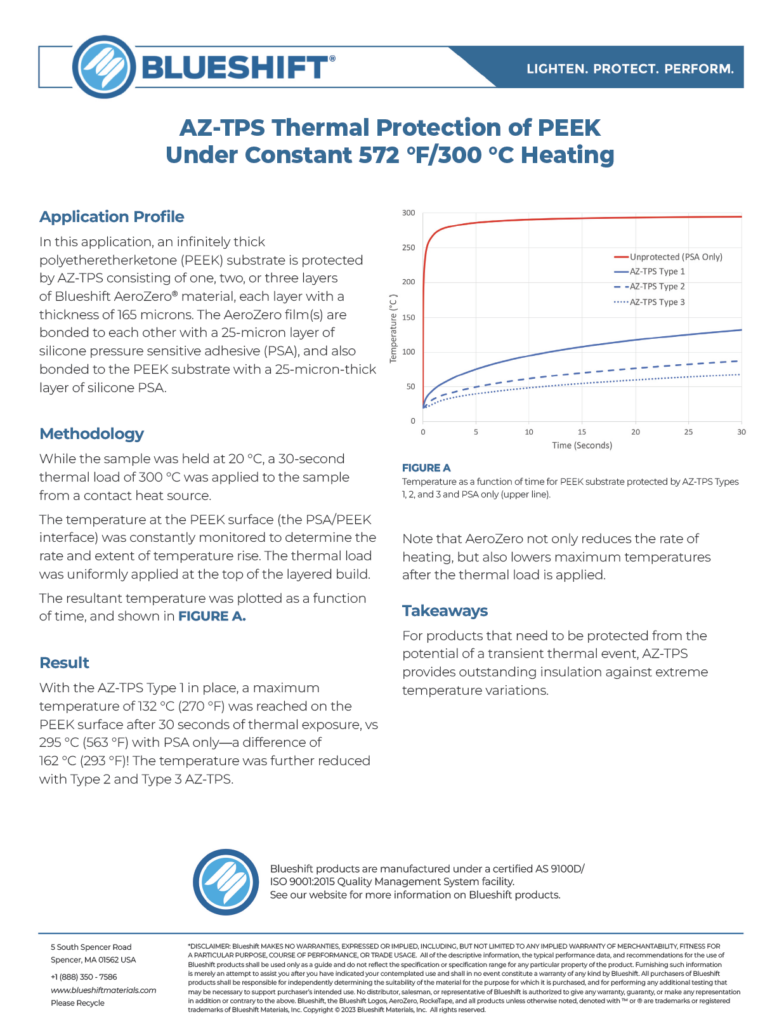

Thermal Protection Systems

Our TPS include our signature AeroZero® technology, a substrate of your choice, + an adhesive.

Rocketape™

Our off the shelf offering. RockeTape can be purchased in a small roll format and kept on hand for emergency situations.

Features of AeroZero

Lightweight & Thin

The thinnest, most flexible, and lightest weight thermal protection system on the market

RF Transparent

Our material allows signals to transmit easily through

PTFE Alternative

Our material is non-fluorinated and is a great alternative for PTFE

Low Dk & low Df

Where speed, consistency, and purity are the biggest considerations

Lighten. Protect. Perform.

Have confidence with Blueshift.

Unlock the potential of your designs with Blueshift today.