Who We Are

Blueshift’s talented team of material experts has been growing steadily since the company’s inception in 2013. From California; to Scotland; to Texas; and finally to Massachusetts, Blueshift has gathered minds from across the world to help create more sustainable aerospace, defense, and specialty electronic solutions. By leveraging its polymer aerogel technology platform, Blueshift empowers product designers with unique, high-performance solutions that promote energy efficiency. Aerozero® is composed of 85% air allowing our products to lead the way in sustainability.

01

Safety and Wellness

Safety is deeply engrained in our culture, and is the focus in everything we do.

02

Customer Focus

We put our customer needs at the center of our activities, diligently sharing expertise and technical know-how.

03

Agility

We understand our responsibilities, proactively target our priorities, adapt to changes with agility, and anticipate future market needs.

04

Urgency

We execute with discipline and urgency, allowing us to exceed customer expectations and planned timeframes.

05

Excellence

We perform at the highest level in all that we do and aim to achieve excellence leveraging our core values.

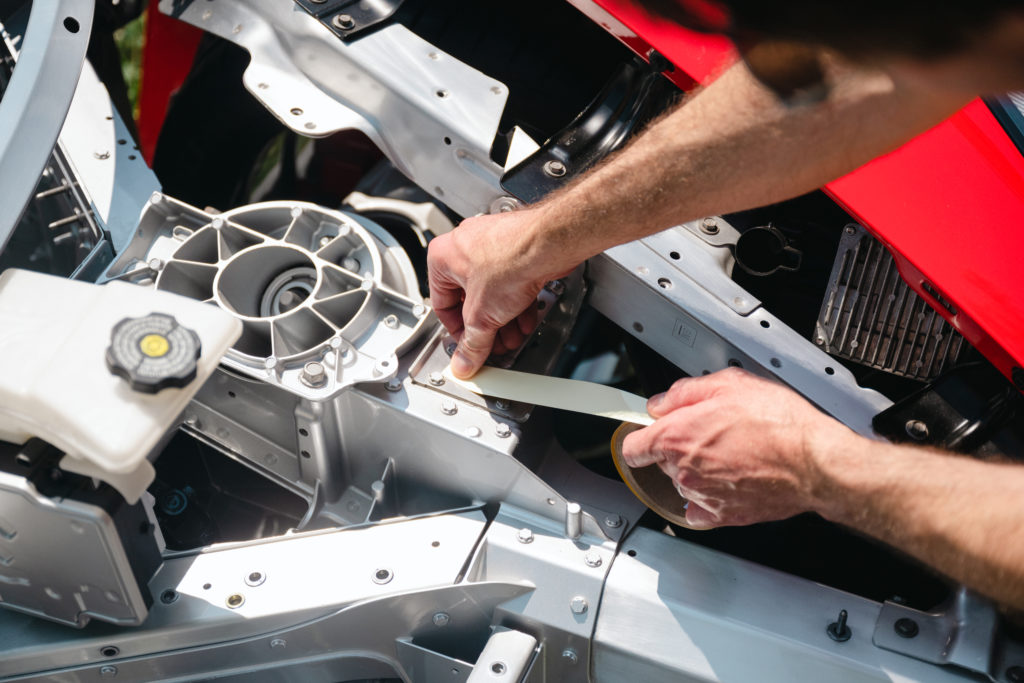

See our Solutions at Work

We package the world’s leading combination of thermal diffusivity, thermal conductivity, RF transparency and thinness of profile in easy-to-use product offerings.

Our patented Aerozero® technology can be combined with other substrates making it the perfect solution when temperature or space restrictions exist that impede the use of legacy insulators.

Let's Work Together

Contact us to chat with our team of thermal specialists and learn more about how our skills & products can help you achieve your goals.